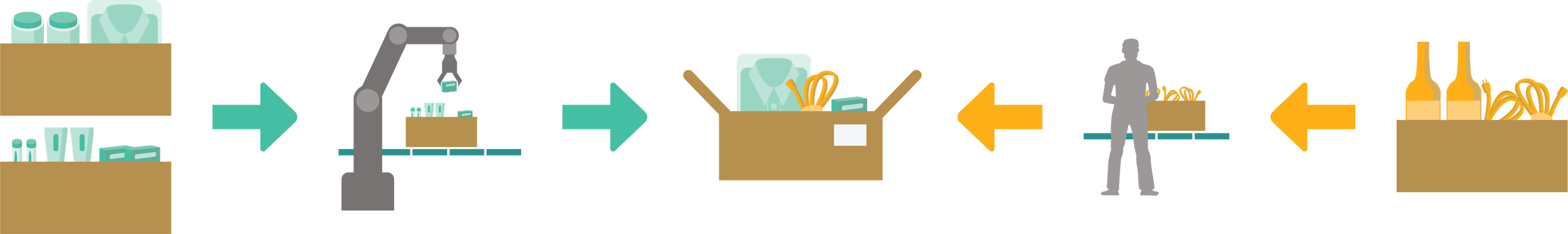

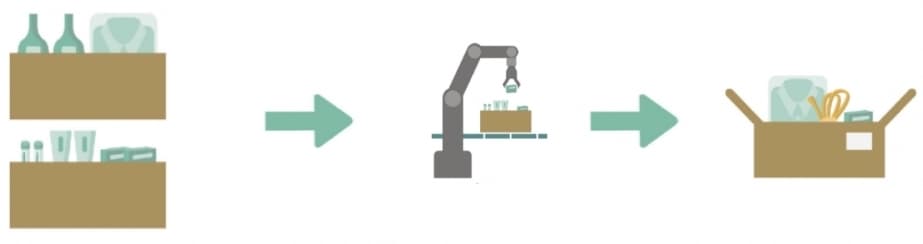

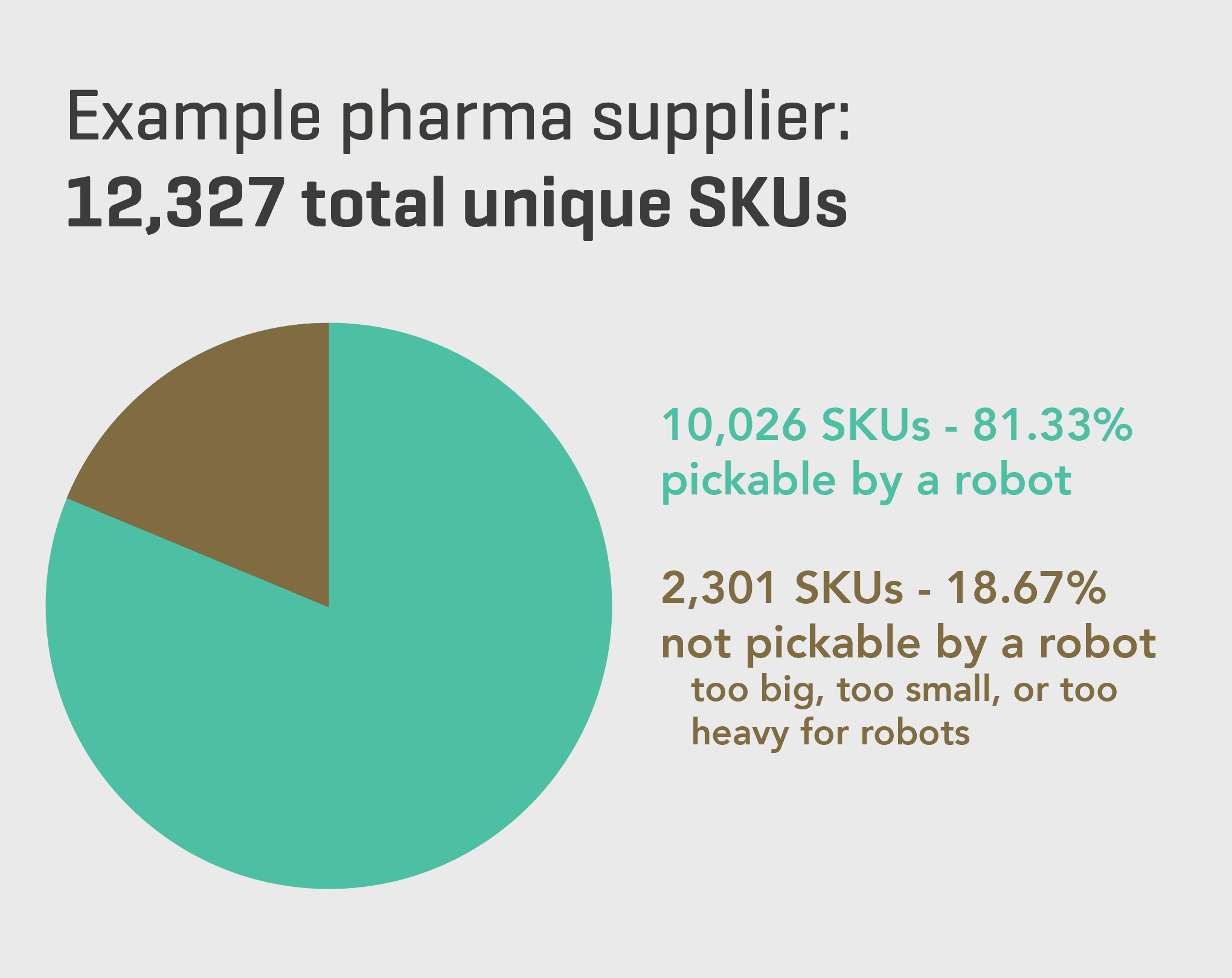

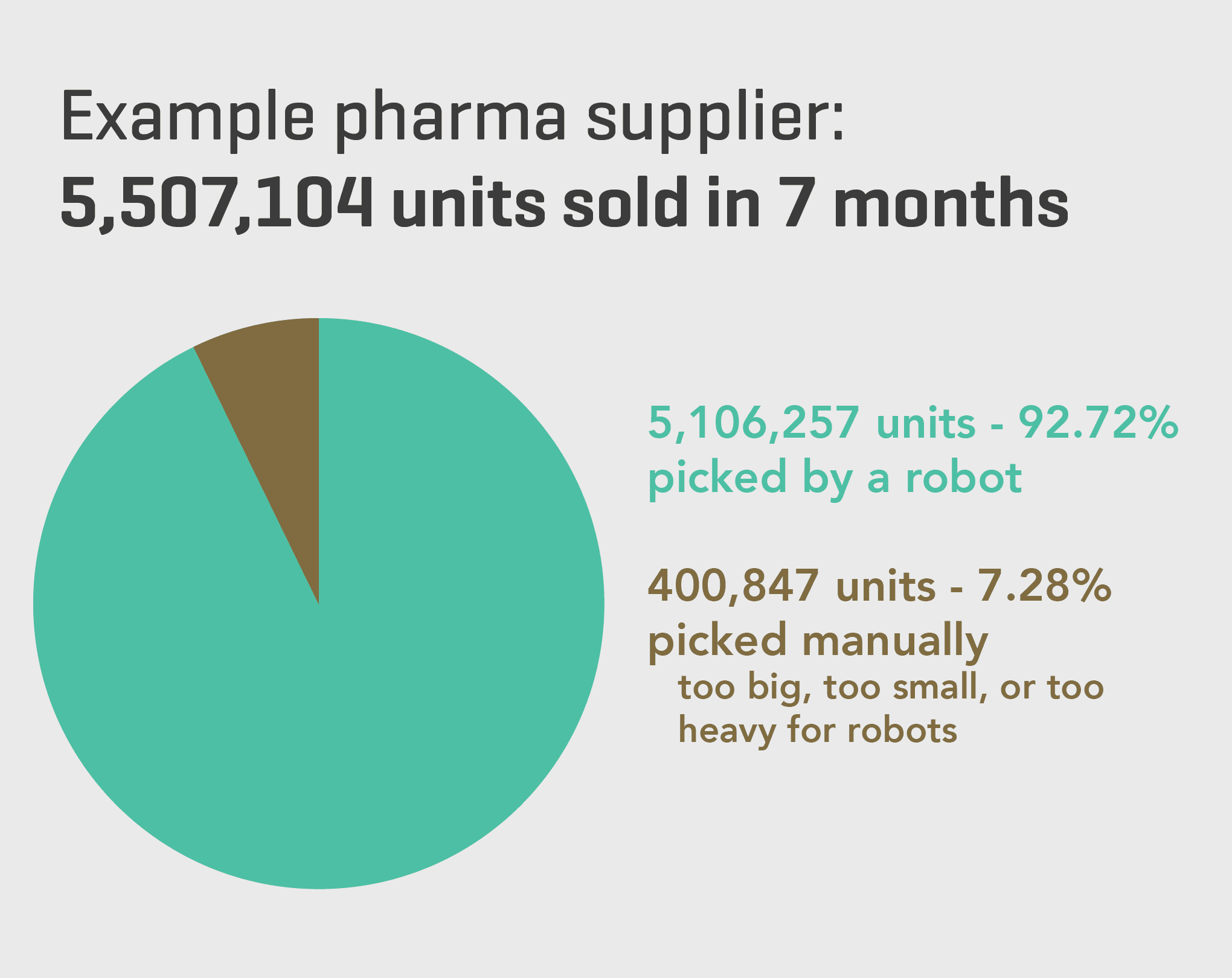

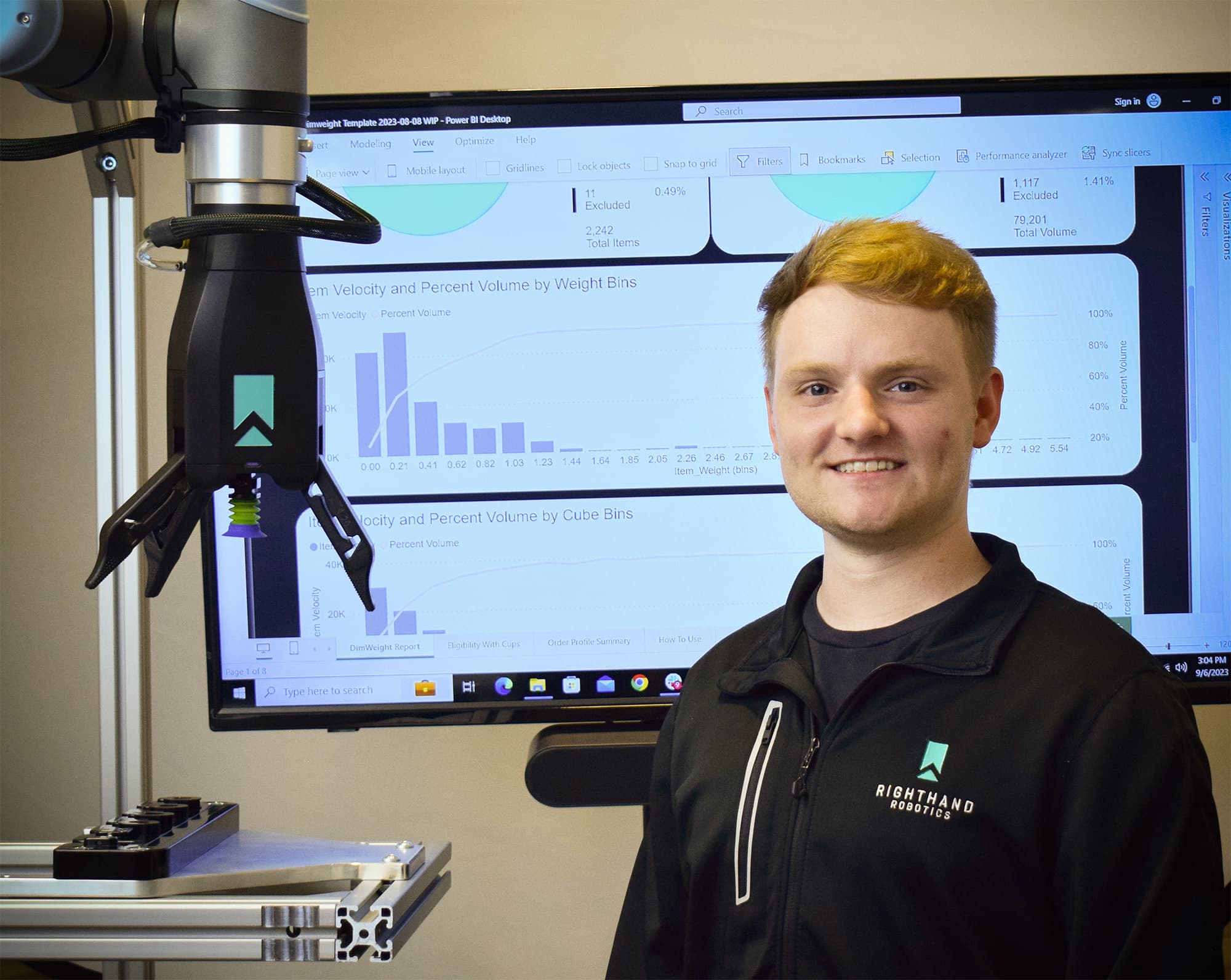

Item Qualification

When building a business case for robotic piece-picking, the first thing to consider is how much inventory is addressable by robots. Thanks to its best-in-class gripper and fleetwide machine learning, the RightPick system can pick the widest range of SKUs with minimal to no custom engineering, reducing cost, increasing scalability, and taking into account constant changes in warehouse inventory.