Entry 62336

Episode 308: RightHand Robotics at MODEX 2022

Read More

The RightPick™ robotic piece-picking system keeps goods flowing cost-effectively as part of an overall path toward a digitized pharmaceutical and healthcare supply chain. When consistency and traceability are critical and demand is growing, the RightPick system meets that challenge by consistently picking products quickly and accurately. The robotic picking system’s multifunction smart grippers combine sensing, suction, and compliant fingers for exceptional handling, even from tightly packed totes.

The RightPick robotic piece-picking system provides comprehensive accountability for all key performance metrics, and “owns the pick” by generating useful data that helps to further optimize performance over time. This includes built-in barcode-reading capabilities, allowing the system to scan and verify items for product traceability and order validation as part of a quality management process.

In addition to 1D barcodes, the RightPick system can handle 2D codes, which are an important part of the drug safety infrastructure in the United States. Using 2D barcodes helps the FDA accurately track product identifiers and helps health care providers capture complete, error-free data about vaccine inventory and administration, according to the CDC. This capability will prove critical when the requirement to use 2D codes goes into effect in the United States.

For additional flexibility, the RightPick system features machine learning algorithms that improve the system’s overall piece-picking capabilities as it works with single-SKU or subdivided totes over time, and adapting quickly to an ever-evolving mix of products, with less manual effort required.

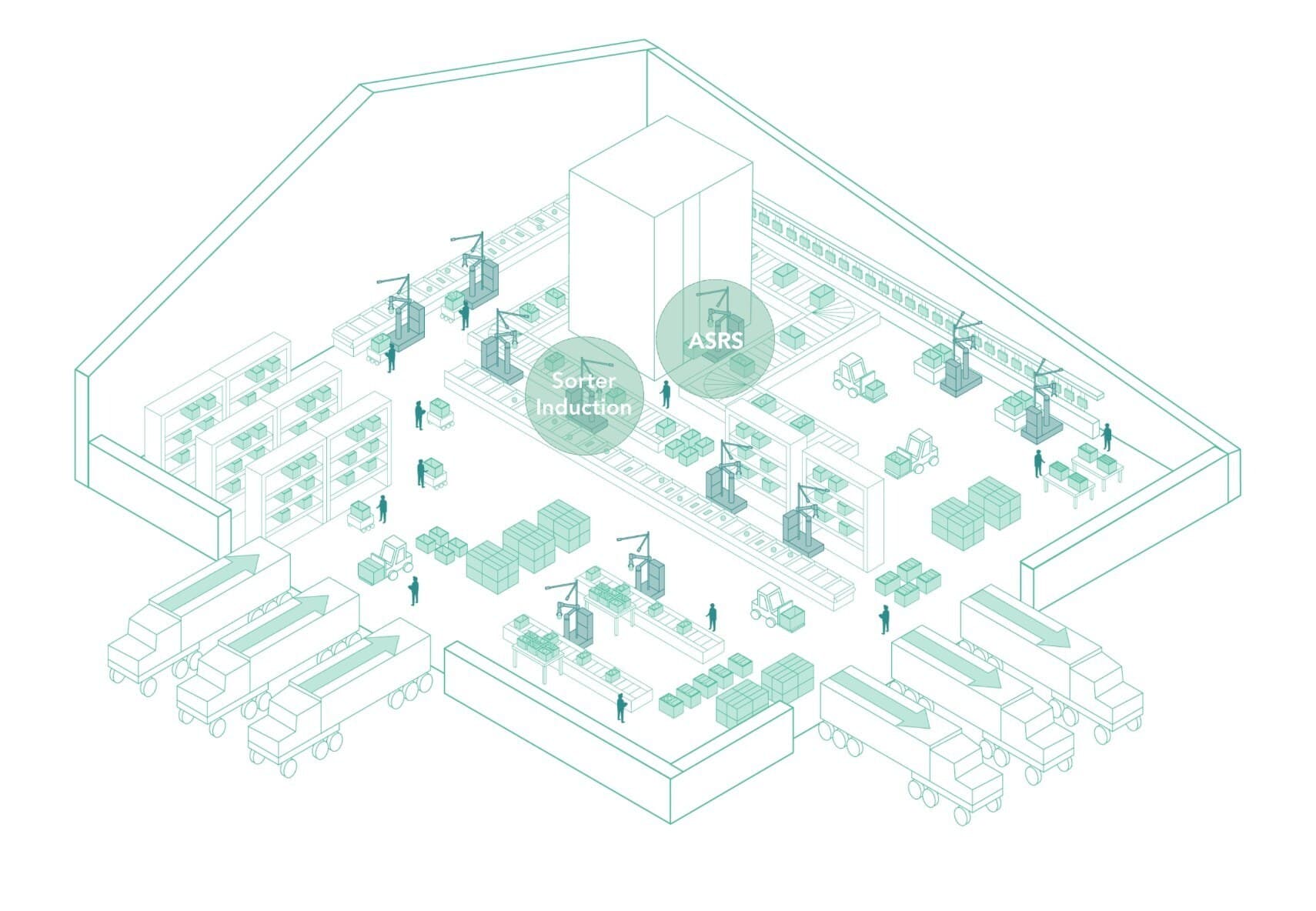

Pharmaceutical and healthcare companies need a piece-picking system that can be quickly and easily deployed and integrated into existing workflows to immediately add value. Many warehouses use goods-to-person automation solutions, whereby products automatically show up on time at a given work station for order fulfillment. Automated storage and retrieval systems (AS/RS) are primary examples. These systems help organize and track inventory, often managing thousands of different items in a relatively small footprint. In a typical setup, mobile robots move within a structural grid framework to pick and deliver goods from bins or totes. When the AS/RS is directed by warehouse software to start an order, a robot retrieves the appropriate bin from its inventory storage location and delivers it to a workstation for order fulfillment or replenishment. A robotic piece-picking system can then transfer the item from the bin to an outbound container.

Companies looking to add piece-picking capabilities to an existing AS/RS require a robotic system that can be easily integrated into the overall workflow. The piece-picking system’s design must factor in the robot’s maximum reach and should promote the efficient flow of goods from one or more source totes to outbound containers, such as order cartons or transfer totes. The RightPick robots easy-to-use application programming interface simplifies this process, allowing efficient incorporation into existing warehouse software and systems, enabling a variety of standard workflows.

Episode 308: RightHand Robotics at MODEX 2022

Read More

RightHand Robotics, a leader in data-driven, autonomous robotic picking solutions for order fulfillment, announced today that Gartner, the global research and advisory firm, has recognized the company as a Representative Vendor in its 2022 “Market Guide for Intralogistics Smart Robotics.”

Read More

The new customer solidifies RightHand Robotics leadership in growing online pharmacy market.

Read More